plate bending test machine|flexural strength testing machine : exporter The 15 Ton Strap Bender is a highly portable piece of destructive weld testing equipment. The Strap Bender works horizontally or vertically, making it an . As cenas de tortura e de perversidade humana enviadas por .

{plog:ftitle_list}

Resultado da 22 de jul. de 2023 · Looking for information on the manga God Jangsan Tiger? Find out more with MyAnimeList, the world's most active online .

Performs guided bend and tensile strength pull tests. Accurately perform tests up to 51,500 pounds of pressure. Optional choice of die and plunger sets to meet ASME or API code. .The 15 Ton Strap Bender is a highly portable piece of destructive weld .

The Model BT1D is our newest bend tester. It uses a new generation design that replaces and improves upon our classic Model BT1B design. It is adjustable for the typical range of tests .The 15 Ton Strap Bender is a highly portable piece of destructive weld testing equipment. The Strap Bender works horizontally or vertically, making it an .3-point flexure test kit for small plate bending test on metallic mate‐ rials Distance gauge for standard compliant positioning of the flexure test kit PI 345 1223 Applications The VDA 238-100:2020-07 is the basis for the test arrangement. This 3-point flexure test kit is used to perform small plate bending tests for determination ofUniversal Testing Machine Malaysia design to determine tensile tests properties like ultimate tensile strength, yield strength, breaking strength, elastic modulus, tensile stress and maximum elongation. compression test, bending test, .

Here is a comprehensive guide to the top 10 metal plate bending machines designed for unparalleled precision workmanship: Accuracy and Repeatability. Precision bending machines boast exceptional accuracy, consistently producing bends to within tight tolerances. They employ advanced control systems that ensure repeatable results, minimizing .TTRBM Rebar Bend and Re-bend Testing Machine is specially designed to test bend resistance performance of reinforced rolling steel bars, building steel reinforcements and steel plates which completely meet the requirement of ASTM A615, ASTM A615M, ASTM E290, BS 4449, DIN 488-2, API 5L, ISO 15630-1, ISO 7438 and other international/national . Small-scale bending tests (Fig. 7) provide a simply fixable set-up for anchors characterization in combined shear-bending and even in equilibrium critical application.It is probably the closest combination of stresses to simulate a real-scale bended structure, which is possible through a small-scale test [97].In this case, recovery of characterization data from the .

Multi-Strand Wire Tensile Test. Fastener Tensile Test. Plate Steel Tensile Test with Automatic . Contacting Extensometer Reinforced Bar Bend Test. 01. Metals Solutions. From automotive sheet metal to reinforced bar, pipe, and tubing, Instron ® high force testing systems are ideally suited to meet all of your metals testing needs.Bend Tester. Lesson topics: 1. Welding Safety – PPE 2. Parts of a WPS 3. Reading a WPS 4. Nondestructive and Destructive Testing 5. Prepare to Weld for a Bend Test Qualification 6. Welding a Qualification Test 7. Preparing to Bend and Examining a Bend for Qualification 8. Welding Career Opportunities. Teaching hours: 15 EN1288-3 gives a schematic description of the test setup for the four point bending test (Fig. 1). This description is a vastly simplified version of the actual testing equipment used in most industrial applications and labs. Therefore, it can be interpreted in different ways resulting in different values for k e from theoretical calculations .

weld guided bend test equipment

Catangiu A. et al (2011) presented results of plane bending fatigue experiments conducted on composite plates of orthogonal glass fibers woven and epoxy resin. The set up of plane bending fatigue is described. It is reported that the stratified composite materials have a better fatigue behavior if the angle of fiber direction and the direction . This video shows you how to first perform a visual examination on a groove weld according to the AWS D1.1 Structural Steel welding code. It then shows you h.

A tensile tester, also known as a pull tester or univeral testing machine (UTM), is an electromechanical test system that applies a tensile (pull) force to a material to determine the tensile strength and deformation behavior until break.. A typical tensile testing machine consists of a load cell, crosshead, extensometer, specimen grips, electronics and a drive system.

Work with us to find the right equipment for your bend testing Jump to: Bend Testing Equipment Bend Fixtures Image Gallery Videos Bend Testing Articles Bend Testing Universal Testing Systems ADMET material testing systems accurately and reliably measure the flexural properties of metals, concrete, plastics, medical devices and other

ASTM D790 or ISO 178 covers flexural properties for plastics; ASTM E855 is used for properties of flat metallic spring materials; ASTM C1684 or C1161 covers 3-point bend testing of ceramics. In a 3-point bend test, the convex side of the sheet or plate is placed in tension, and the outer fibers are subjected to maximum stress and strain .

TEST CHART FOR PLATE BENDING MACHINES 1 SCOPE This standard describes both geometrical and practical tests on plate bending machines and corresponding permissible deviations. 2 PRELIMINARY REMARKS 2.1 Before carrying out thetests, machines shall be levelled in accordance with the manufacturers instructions which should be supplied, in sufficient Some common weld tests include Visual Inspection, Bend Testing, tension test, visual inspection, and radiography testing. Welders must be able to produce high-quality welds that meet the requirements specified by . Figure 1-18 Z-shaped step bending. VI. Bending by Press Brake Machine. There are two categories of bending machines: ordinary bending machines and CNC bending machines. CNC bending machines are .

In the 2-point flexure test, the specimen is gripped at one end and loaded with a test die on the exposed side.. The 2-point flexure test kit is suitable for testing paper, cardboard, and films. It is used to determine the bending stiffness . A plate bending machine is a specialized tool used to shape metal plates into various angles and forms. It is a versatile machine that can be used for a variety of applications, including manufacturing, construction, and repair work. Types of Plate Bending Machines. There are three main types of plate bending machines:12 Ton hydraulic manual and pneumatic guided bend test jig fixture for weld testing. Includes standard P-1 plunger. Other plungers are available at an additional cost. This bender is an easy and inexpensive way to test welders. Also known as Guided Bend Roller Jig or Weld Test Strap Benders. Can be shipped UPS - Freight Charges are additional. .

1.1 These test methods cover bend testing for ductility of materials. Included in the procedures are four conditions of constraint on the bent portion of the specimen; a guided-bend test using a mandrel or plunger of defined dimensions to force the mid-length of the specimen between two supports separated by a defined space; a semi-guided bend test in .3 ph stainless steel pyramid type plate bending machine, for. 3-Roller Symmetrical Plate Rolling Machine; Have a Question? Ask our expert. Speak your question. Please enter your question. Watch Video. Pre Pinching Plate Rolling Machine ₹ 16,00,000 Get Latest Price.Wide Range of Machines The standard range of 3-roll plate bending machines covers plate thicknesses from 3 mm (1/8”) to 100 mm (4”) and widths from 1 000 mm to 8 000 mm (3’ to 26’). All machines have unique features needed for high precision and versatility: • Prebending of both the leading and trailing edge. In many

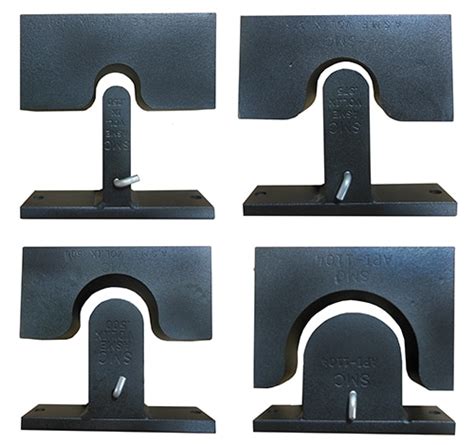

The equipment is mainly used for the wide and thick plates produced by Iron and Steel Group Corporation for bending test. Wide and thick plate varieties include pipeline steel plate, shipbuilding steel plate, structural steel plate, boiler steel plate, container steel plate, atmospheric corrosion resistant plate, construction machinery plate, etc. Common factors affecting bending coefficient: thickness; material; die width; die tip R; punch tip R; material’s rolling; others; Material’s Properties. 1. The impact of plate thickness on the stroke. If the thickness of the plate increases, the stroke of the bending angle will be decreased. (The thicker the plate, the smaller the V/t)FLEX / BEND TESTING MACHINE Components and Parts. . Adjustable span for "U" bend tests of plane plate or welded flat specimens. Fixture consists of a T-slot base with adjustable span supports (0 - 254 mm) supported by two tie rods. Maximum specimen width up to .

Train & qualify welders quickly and accurately with destructive test equipment from Triangle Engineering. Heavy, rugged construction provides long service life. Train & qualify welders quickly and accurately with destructive weld testing equipment from Triangle Engineering.W-6810 | Guided-Bend/Weld Bend Test Fixture. Guided-Bend / Weld Bend Test Fixture, Adjustable Span for "U" bend tests of plane plate or welded flat specimens. Fixture consists of a t-slot base with adjustable span supports supported by two tie rods. Fixture specifications: Span - 0 to 254 mm (10.0 in) Specimen width - up to 76 mm (3.0 in)

guided bend testing equipment

drive scan to test hard drive imac retina late 2015

drive test questions charles hard

drive test really slow hard drive

four point bending test procedure

WEBPlay now! Caesars Slots – The Best Free Slots Casino Game. Welcome to Caesars .

plate bending test machine|flexural strength testing machine